Photo Gallery

Tunnel Ventilation Project

-

Metro’s Tunnel Ventilation contractor used railroad flatcars to transport tools and materials to the worksite in the tunnel. This supply delivery method avoided disruption to motorists, residents and businesses. -

To house powerful new tunnel ventilation fans, a “second floor” was built over the tracks. Two massive steel bridges were built across both tunnels. Here, the steel decking is being welded in place to support a concrete floor. -

To maximize work production and safety, Metro used a new plan separating the work zone in the tunnel. Here, workers are installing a rope and mesh barrier system. The barrier system allows work to continue 24/7 avoiding disruption to train service. -

A diesel-powered work train known as a Prime Mover moves a man-lift into the trackside space prior to mesh barrier installation. This lift was used to remove the existing wall of louvers and worker platforms seen in this image. -

To start construction of the steel “second floor” across both tracks, workers installed the first beams at the base of a deep vertical shaft away from the tracks. Each steel beam was carefully moved from the flatcar to its overhead location. -

Aerial view of a ventilation shaft passage between the inbound and outbound tunnels. Here crews are preparing to install several vertical columns that will support the second floor and bridge across the tracks. -

New steel vertical columns and beams that will support the second floor over the tracks. -

Frame for the second floor over the tracks. -

Due to the significant space limitations in the tunnel, and the longer length of the steel beams, special handling was necessary. Here, workers use the station platform for proper alignment before rolling down the tracks and setting the steel beams. -

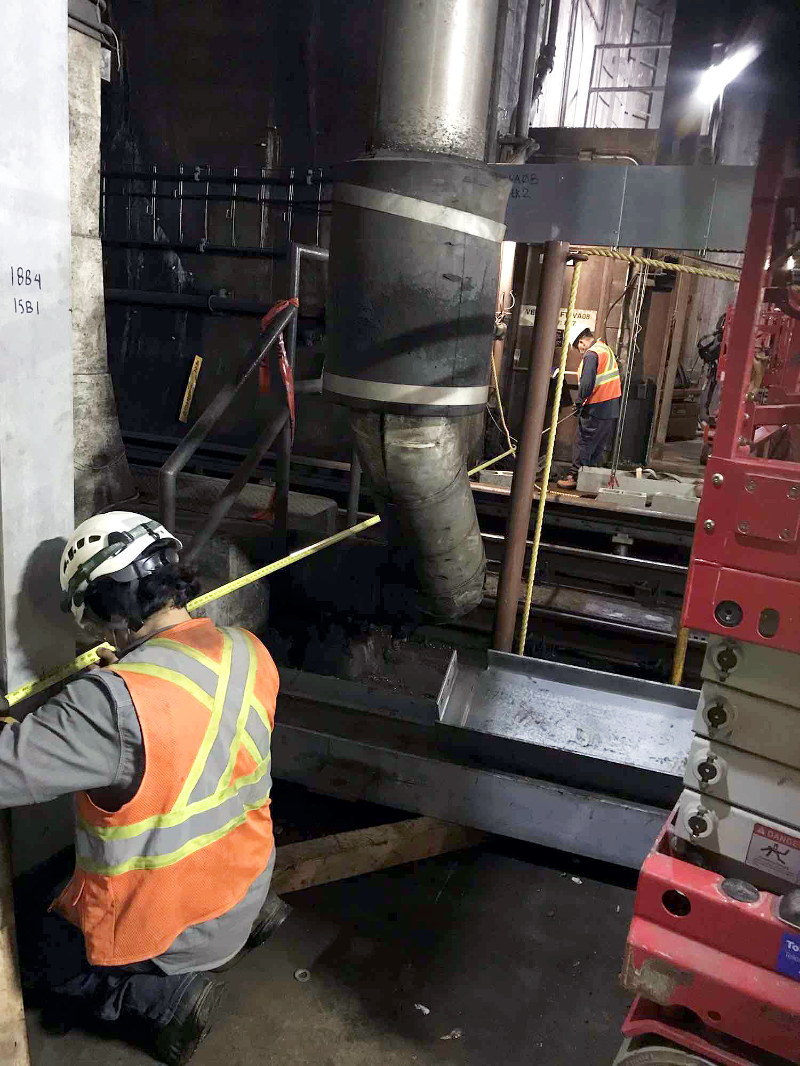

Before installing the steel frame over the tracks, workers performed with both laser and hand measurements. Here, workers hand measure steel column locations on each side of the tracks.